GFS

Glass Fused to Steel (GFS) bolted panel tanks combine the strength and design flexibility of steel, with exceptional corrosion resistance and hygiene benefits of glass. GFS is an inert Vitreous Glass Enamel coating, applied to 100% of the surface area of each steel panel and fired at 830-850°C to create a mechanical and chemical fusion bond between the glass coating and the steel substrate. The finished coating has a strong resistance to algae and bacterial growth, and is excellent for potable water storage, as well as storage of a wide variety of more corrosive water and wastewater media.

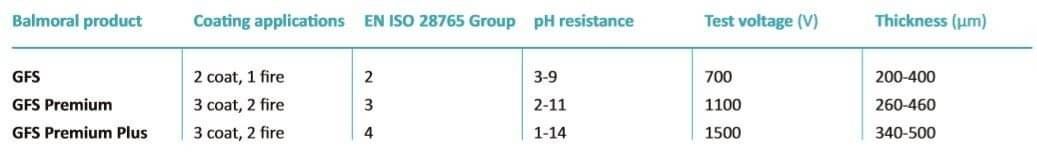

The GFS coating exhibits a hard, tough surface which is impervious to liquids and vapours, and is highly UV resistant. Tasman Tanks' range of GFS tanks is available in 3 coating specifications, providing coating thicknesses ranging from 200μm to 500μm. In consultation with the designers, Tasman Tanks will select the optimal coating to suit your application, based on performance criteria & water quality data as provided by you, the client.

Benefits of GFS

- Strong and visually aesthetic coating

- Super resistant coating

- Same strength and flexibility as steel

- Unaffected by UV rays

FBE

Fusion Bonded Epoxy (FBE) coated steel bolted panel tanks have been successfully utilized throughout the globe for many decades in the storage of potable, process and waste waters. FBE is a factory applied, thermoset polymer coating, bonded to the steel substrate at 200°C, creating a strong & flexible coating. FBE provides high durability to impact, low cost manufacturing, low carbon footprint and efficient design principles. FBE tanks are tested to stringent standards as glass coated steel is and meet, exceed or provide comparable performance against a wide range of internationally recognised coating requirements.

Being a factory applied coating, in a controlled environment, there is no risk for inconsistent quality or poor adhesion issues, as is commonly encountered with field applied coatings. Tasman Tanks' range of FBE tanks is available in 2 coating specifications, providing coating thicknesses range from 180um to 400um. FBE tanks are also extensively used for Anaerobic Digesters & the storage of demineralized water. In consultation with the designers, Tasman Tanks will select the optimal coating to suit your application, based on performance criteria & water quality data as provided by you, the client.

Applications for FBE tanks include, potable water storage, agricultural waste and municipal water.

Benefits of FBE tanks

- highly corrosion resistant

- durable

- available in a large range of colours

All FBE panel tanks meet the BITLPFS.02 and BITLPFS.03 standards.

Tasman Tanks works with Balmoral Tanks, of Thurnscoe England, to import GFS and FBE Tank. panels.